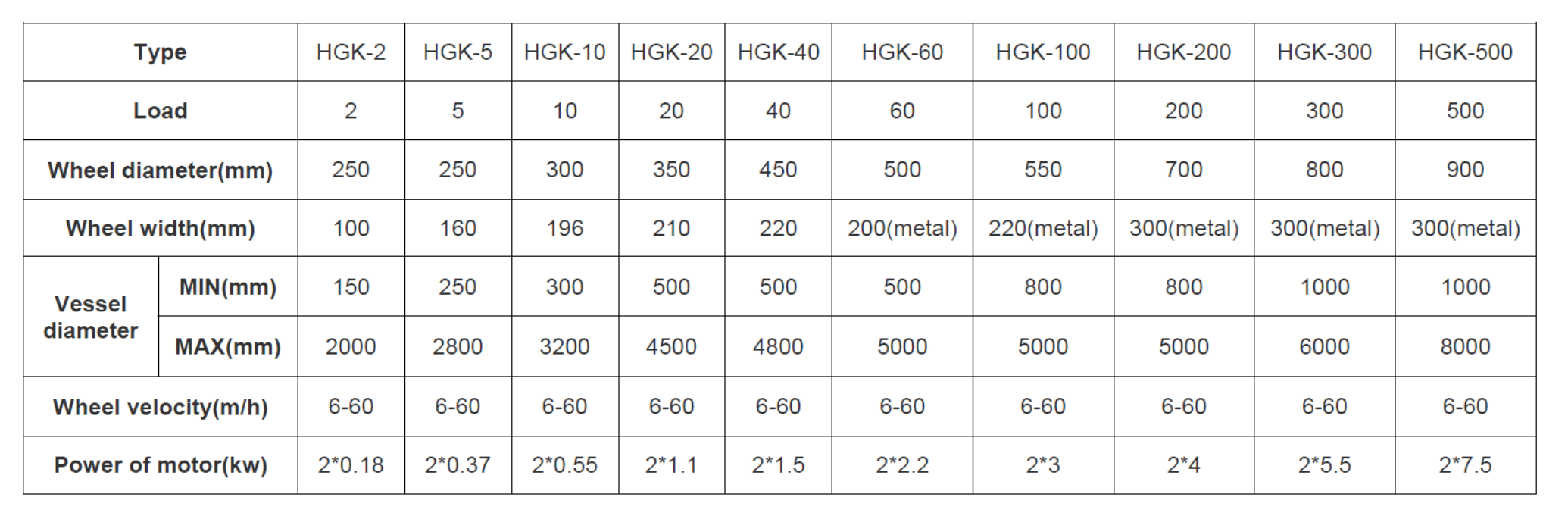

Wuxi ABK is the original manufacturer of HGK welding rotators (2-800T capacity), specializing in high-precision welding solutions for circular metal containers used in oil & gas, pressure vessels, and pipelines. Our rotators are equipped with adjustable rollers, worm gear reducers, and digital controls to ensure exceptional accuracy and performance.

We offer fully customizable solutions, including drive/idle rotators, reinforced bases, and remote control systems, tailored to meet your specific needs. With over 20 years of industry experience, Wuxi ABK delivers durable, factory-direct equipment backed by reliable technical support.

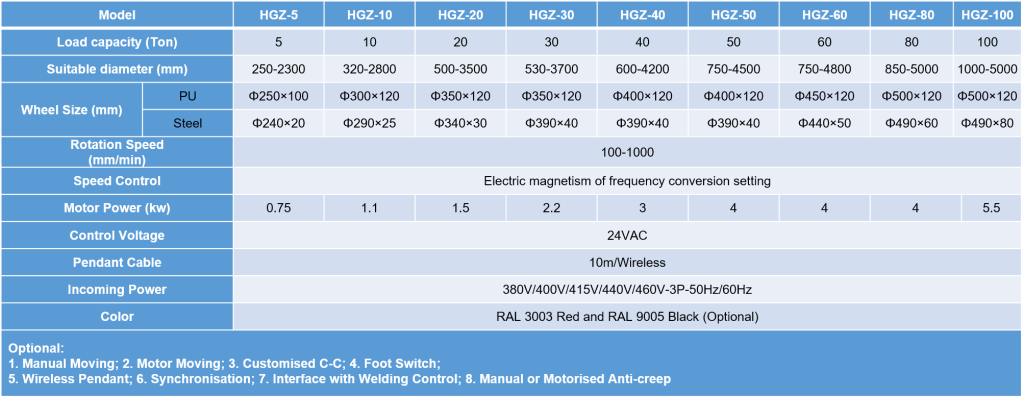

Wuxi ABK, the original manufacturer of self-aligning rotators, combines 20+ years of expertise with cutting-edge technology to deliver high-precision, durable solutions for a wide range of industrial applications. Our HGZ series rotators are designed for optimal performance, supported by stringent quality control and a highly skilled technical team.

As a factory-direct supplier, we provide reliable products, competitive pricing, and fast technical support. Whether you need standard or customized solutions, Wuxi ABK offers top-quality welding rotators tailored to your specific requirements.

Wuxi ABK is a leading manufacturer of welding auxiliary equipment, offers high-performance welding rotators, including PU wheel, hydraulic lift, and fit-up rotators. Designed for demanding applications in pipelines, wind towers, and pressure vessels, our rotators ensure unmatched precision, durability, and reliability.

We provide fully customizable solutions to meet unique industry needs, ensuring seamless integration into your workflow. As a factory-direct supplier, we deliver premium-quality products at competitive prices, backed by expert technical support.

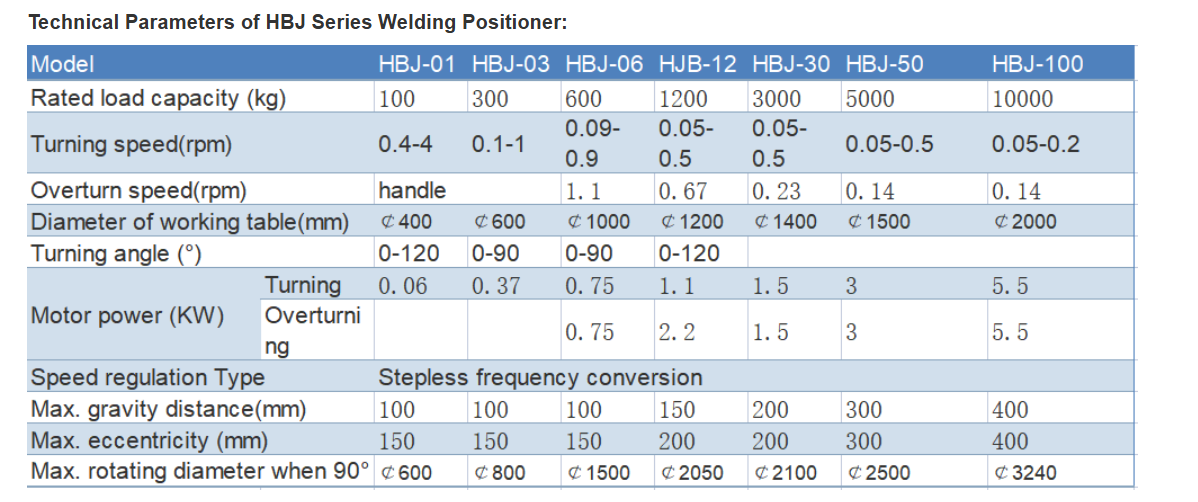

WUXI ABK is a leading manufacturer of welding positioners, providing high-precision positioning solutions for special structures, construction machinery, and small round workpieces. Our equipment is engineered with a sturdy worktable, a reliable turning system, and advanced controls to ensure efficient and accurate welding operations.

Designed to meet the demands of industries such as construction, manufacturing, and fabrication, our welding positioners excel in handling complex tasks with ease. As a factory-direct supplier, we offer customized solutions and competitive pricing tailored to your specific needs.

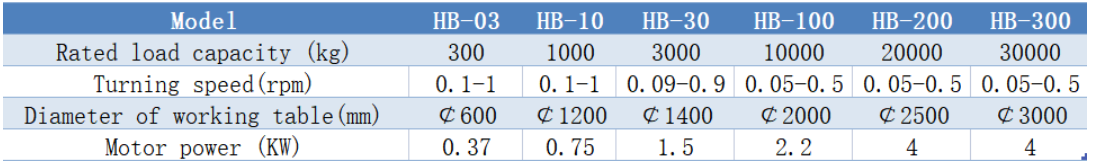

WUXI ABK, a leading factory for welding turntables, provides high-precision solutions for pressure vessels, petroleum, chemical processing, and shipbuilding. Our turntables automate welding, ensuring superior quality and efficiency. Contact us today for factory-direct pricing and customized solutions to optimize your welding process!

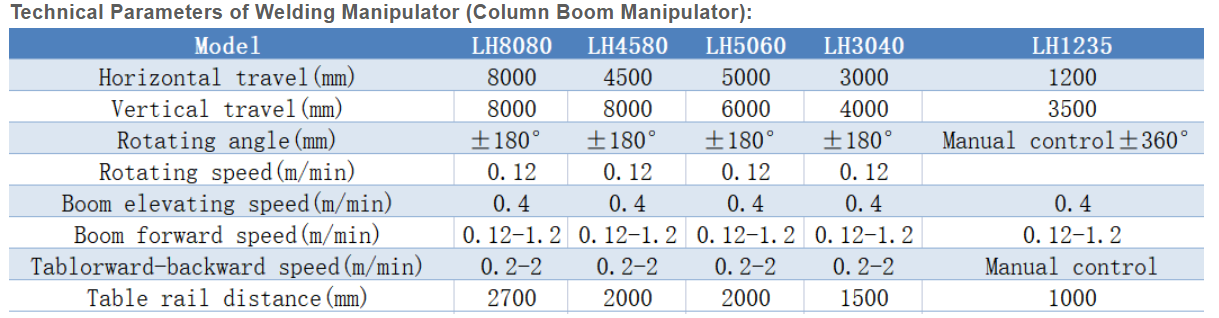

The WUXI ABK Welding Manipulator delivers precise TIG/MIG welding support for vessels, pipelines, and cylinders, ensuring exceptional accuracy and efficiency. Featuring radial, fixed, and rotary configurations, it adapts seamlessly to various diameters and integrates effortlessly with automation systems.

Ideal for industries such as pressure vessels, construction, and chemical processing, our manipulator is designed to handle demanding environments with stability and reliability. As a factory-direct manufacturer, WUXI ABK guarantees cost-efficient, high-performance welding solutions tailored to your needs.

Why choose us

Wuxi ABK is the original manufacturer of welding auxiliary equipment, specializing in welding rotators, welding positioners, and welding manipulators. Founded in 1999 with a registered capital of $1.4 million, we have over 20 years of expertise in delivering high-precision, durable, and customizable welding solutions. Our equipment is widely used in pressure vessel production, oil and gas, shipbuilding, wind towers, construction, and heavy machinery. As a factory-direct supplier, we ensure high quality, competitive pricing, and fast delivery. All products comply with ISO and CE standards and are trusted by customers worldwide. Contact Wuxi ABK today for reliable welding solutions tailored to your needs!

Proven Expertise

With over two decades of industry experience, we have successfully delivered international projects, showcasing our deep expertise and reliability.

High-Quality Products

Our equipment is engineered for exceptional durability, precision, and efficiency, meeting the most stringent quality standards.

Wide Application Range

Designed to serve diverse industries, our products provide tailored solutions to address unique operational challenges.

Competitive Pricing

We deliver high-performance equipment at cost-effective prices, ensuring value without compromising on quality.

Custom Solutions

Our team specializes in creating customizable equipment to perfectly align with your specific project needs.

Mainstream Product

Precision Welding Solutions, Tailored for Your Needs – Get a Free Quote Today!

Precision Welding Solutions, Tailored for Your Needs – Get a Free Quote Today!

Customer evaluation

FAQ

FAQ 1: What industries are your welding rotators and positioners suitable for?

Answer:

Our welding equipment is widely used in industries such as:

Pipeline Construction: For girth welding of large-diameter pipes.

Wind Tower Manufacturing: For precise alignment of tower sections.

Shipbuilding: For continuous welding of hull structures.

Pressure Vessels: For rotating heavy vessels during welding.

Heavy Machinery: For fabricating large components like H-beams.

FAQ 2: Can your welding equipment handle heavy loads and large diameters?

Answer:

Yes, our welding rotators and positioners are designed for heavy-duty applications:

Load Capacity: Up to 100 tons (customizable).

Diameter Range: From 0.5m to 8m.

Precision: ±0.05mm alignment accuracy.

FAQ 3: Do you provide customized solutions for specific welding needs?

Answer:

Absolutely! As an OEM manufacturer, we specialize in customizing welding equipment to meet your exact requirements:

Tailored Designs: Adjust torque, speed, and dimensions.

Special Features: Add hydraulic lift, remote control, or anti-slip PU wheels.

Quick Turnaround: Prototype delivery within 30 days.

FAQ 4: How do you ensure the quality of your welding equipment?

Answer:

We follow a strict quality control process:

Material Inspection: Only use certified steel and components.

Pre-Assembly Check: Laser alignment of frames.

Final Testing: 72-hour continuous operation under load.

Certifications: CE, ISO 9001, and SGS approved.

FAQ 5: What kind of after-sales support do you offer?

Answer:

We provide comprehensive support to ensure your satisfaction:

Warranty: 1-year warranty on all equipment.

Technical Support: 8-hour response via email, phone, or WhatsApp.

Maintenance Guides: Step-by-step manuals and video tutorials.

Spare Parts: Lifetime availability of critical components.

FAQ 6: How long does it take to deliver the equipment after ordering?

Answer:

Our delivery time depends on the order complexity:

Standard Models: 15-30 days.

Customized Solutions: 30-45 days.

We also offer expedited shipping for urgent projects.

1.Still have questions? Let our experts help you find the perfect welding solution for your project. Get a Free Consultation Today!

2. Want to explore our full range of welding equipment? Download our Product Catalog for detailed specifications and technical data.

3. Need immediate assistance? Our technical team is ready to help. Contact us now for expert advice and support!